The Premise

For the majority of the design cycle, we focused on designing an elevator mechanism of some sort to lift the container that house the agents we retrieved onto the zipline before sending the container down. While we were able to successfully implement this solution, we later opted for a more passive, mechanically constrained solution that featured torsional springs.

CARABINER

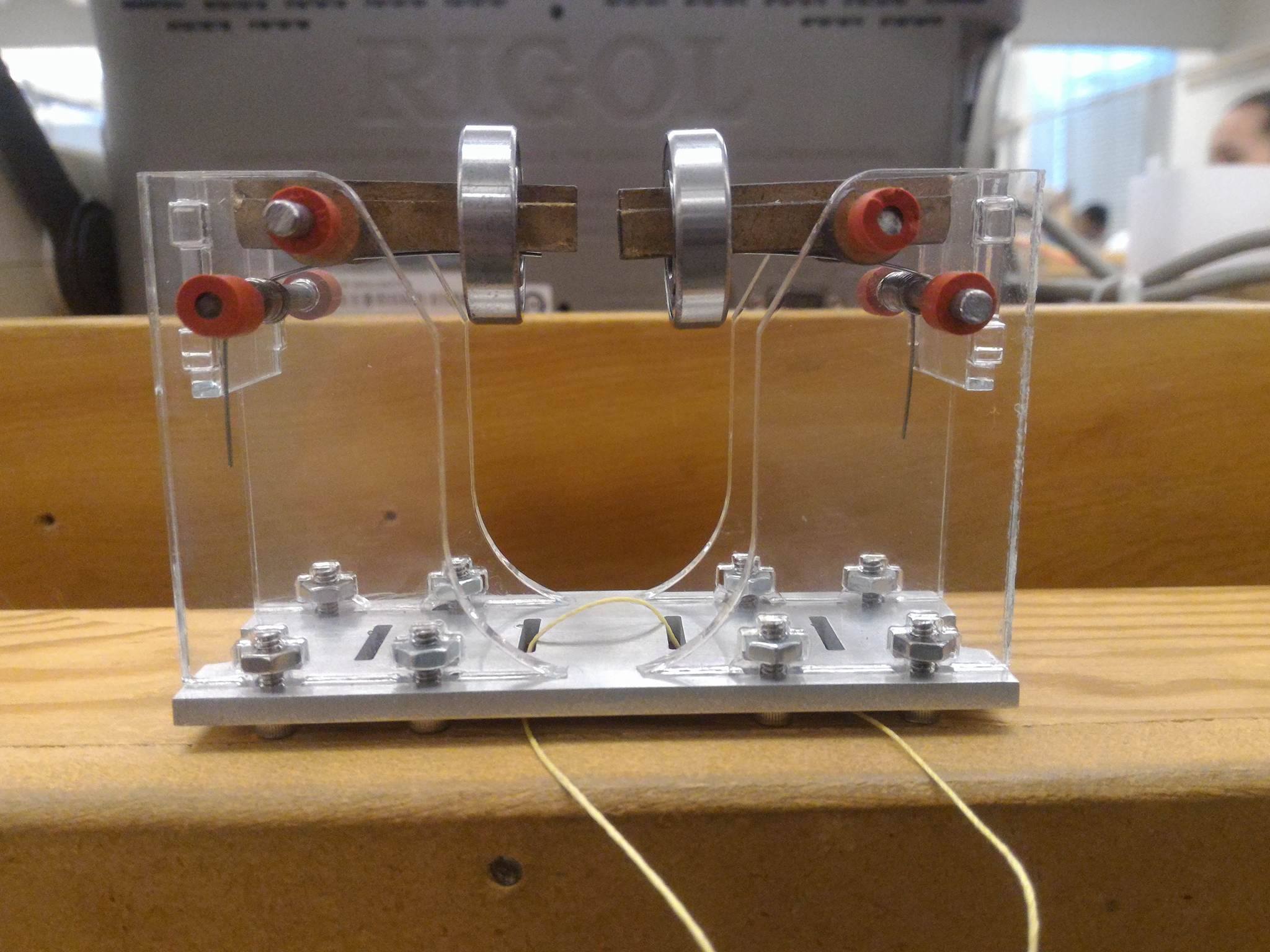

Our initial concept for a zipline mechanism was to use a a carabiner mechanism. It could be pushed open one way, but lock the other way. This would require that we have our robot drive underneath the zipline, elevate the containment unit that has the carabiner attached to it, and lock the containment onto the zipline. This concept was fairly sound, and had two major requirements: we needed to devise an elevation method to lift the containment towards the zipline, and we needed to ensure that our robot drove precisely to a position underneath the zipline. The area around the zipline was unmarked of any tape to follow, so we would need to become creative in the design. The carabiner design itself featured two torsional springs and a mechanical stopper to faciliate its functionality.

DOUBLE RACK AND PINION ELEVATOR

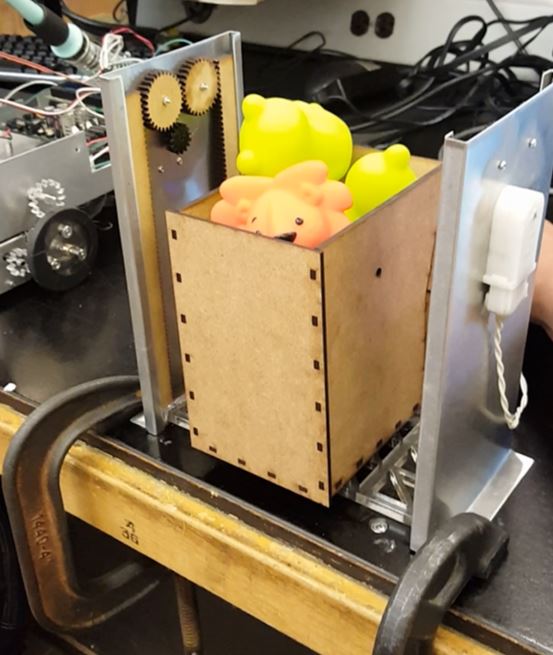

In an effort to find a mechanism to elevate the containment in an easy manner, we designed a rack-and-pinion based elevator. Four racks, two on each side facing each other were driven up by two gears on each side. A motor was used to drive the gears. With two gears, the vertical translation of the racks were always in the same direction. A platform was pitched at the bottom of the racks that would hoist the containment upwards. The major set back of this design was that the two motors had to be syncrhonised with each other perfectly. Most motors had some variable voltage offset that was not easy to compensate for, thus resulting in the racks going up at different rates, leading the plaform to move at a slant. This would occasionally cause the platform to get stuck, preventing any vertical translation of the containment. Inconsistency marred this design, and it became clear a single-motor alternative would be needed.

TIMING BELT DRIVER

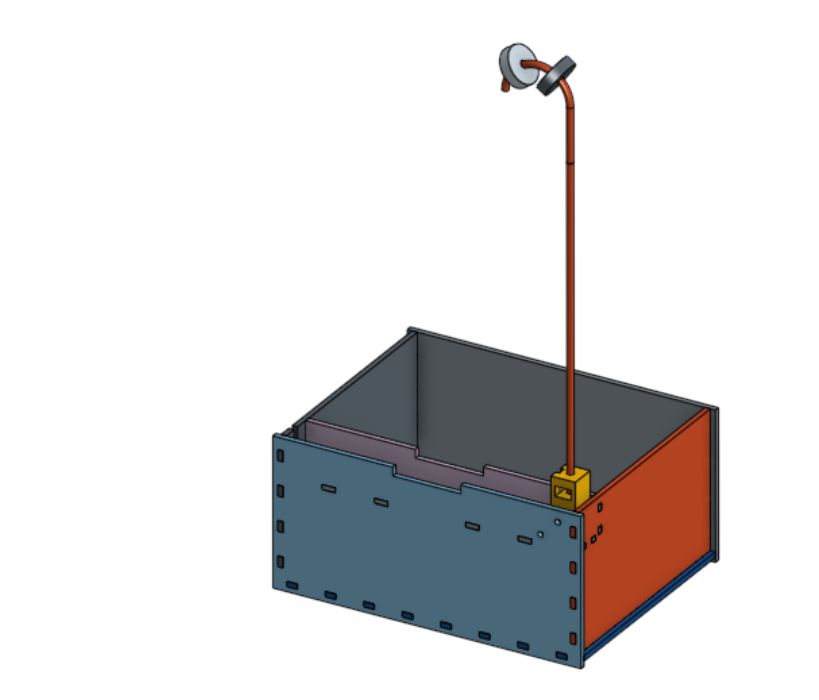

The next design featured a single rack driven by a gear pleaced near the top of the rack. To offset the motor, a timing belt with timing belt pulleys were used. This offset was required because a bending moment would develop in the backboard that guided the rack due to the weight of the motor. This solution was fairly efficient and consistent in doing its job. This solution was ultimately considered as being a part of the final implementation but was subdued from inclusion due to the development of a much more passive solution.

TORSION SPRING HOOK

One of our initial overall design requirements was to favor simiplicity at all junctures. While the timing belt and carabiner idea was effective, it required precise control of driving position, multiple moving parts and features many modes of failure. In the final week of designing, we instaed opted to use a torsional spring that featured a hook. Unlike the carabiner, the hook simply required that our robot drive in the general direction of the zipline. Once the hook reached the zipline it would latch onto the zipline. The torsional spring was used so that the hook could lay flat at the beginning of the run to satisfy an initial height requirement. The chopstick arms were used to hold the hook down as it passed through the entrance gate, but once the arms were engaged to pick up agents, the hook would spring back 90 degrees, before being mechanically stopped by a stopper. This passive solution significantly decreased the risk we assumed in the design.